BCCC expands machinist program

Published 9:13 pm Thursday, June 21, 2012

In an effort to meet the growing need by local industries for machinists, Beaufort County Community College will upgrade and expand its machinist program.

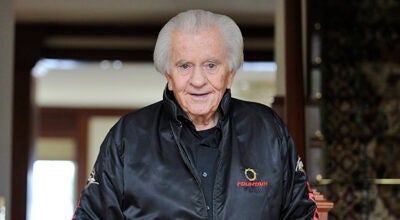

Matthew Lincoln, a BCCC alumnus, will lead the effort to train more skilled machinists to enter the local workforce.

“Most of the machining industry is growing, but that industry needs skilled people, and currently supply isn’t meeting demand,” Lincoln said. “There are jobs in the community.”

A recent study done by the National Association of Manufacturers concluded the largest impediment to future growth is the lack of a skilled work force.

With its plan to upgrade and expand its machinist courses, the college is signaling its commitment to economic development in the region, according to BCCC President Barbara Tansey.

“Providing skilled workers who can meet the demands of local industry and improving the local economy is what the community colleges in North Carolina were created to do,” she said. “By expanding its machinists courses, BCCC is emphasizing its role as a source of technical and job-related training.”

Improving the machinist program at BCCC is one of the activities targeted under the U.S. Department of Labor Employment and Training Administration’s Trade Adjustment Assistance Community College and Career Training Grant. The $2.2 million, three-year grant will include funding for equipment to upgrade machining along with other programs to meet industry needs.

“This grant is particularly important to economic development in the industrial sector for existing companies and for potential companies seeking a highly skilled work force,” Tansey said. “In addition to expansion of BCCC’s training efforts in machining and other industrial-technology programs, the grant has helped the college upgrade its equipment and facilities to meet industry standards.”

Machinists use machine tools that, increasingly, are computer controlled — such as lathes, milling machines and grinders — to produce precision metal parts ranging from simple bolts of steel or brass to titanium bone screws for orthopedic implants. Hydraulic parts, anti-lock brakes and automobile pistons are other widely known products that machinists make.

Some newer manufacturing processes use lasers, water jets, electrical discharge machines or electrified wires to cut the metal pieces. Because the technology of machining is changing rapidly, machinists must learn to operate a range of machines.

Although some of the computer controls of some machine tools are similar, machinists must understand the unique capabilities of each machine.

And as engineers create new types of machine tools, machinists must constantly learn new machining properties and techniques.

“It’s not the machine shop of yesterday,” Lincoln said, adding that machinists today are frequently required to use computer and math skills in the manufacture of industrial parts.

Lincoln will use his 15 years of experience as a machinist to work with local industry to upgrade and expand BCCC’s program to meet the requirements for machinists in the 21st century.

A native of New Jersey, Lincoln graduated from Hopewell Valley Central High School in Pennington, N.J. He moved to eastern North Carolina after his father retired to the area.

After working in various manufacturing and construction positions, Lincoln decided to pursue training at BCCC to help him move to a better career.

Lincoln took machining courses at night, earning an associate degree in mechanical-engineering technology.

His career includes working at Fountain Power Boats and, later, the U.S. Naval Air Depot at Marine Corps Air Station Cherry Point. Before taking the full-time position at BCCC, Lincoln taught machining classes part-time at the college.

Lincoln lives in the Pungo community with his wife, Jackie, who is studying to become a teacher, and three children.

While BCCC has offered machinist courses throughout its history, most recently those courses have been taught by part-time instructors.

With a new full-time instructor, BCCC will be better able to meet the needs of industry, said Wesley Beddard, BCCC dean of instruction.

“BCCC is very pleased to have Matthew Lincoln join us as we revive our machining program,” Beddard said. “He is making recommendations for curriculum program changes and equipment upgrades to help us design a program that will train workers for very good jobs in our service area.”

A computer-controlled lathe, expected to arrive on campus later this month, is one of the first purchases the college will make in its efforts to upgrade the program.

“The machinist program is going to be state of the art,” Lincoln said.

BCCC offers a diploma in machining designed to be completed in one year that includes studies in technical drafting, computer-assisted design, mathematical models and machining technology.

Students in the program may also choose to pursue an associate degree in mechanical-engineering technology.

Once they gain the appropriate skills, students in the program will know a good paying job is virtually guaranteed, much as it is for the college’s top welding graduates.

In 2010, there were about 438,100 machinist jobs nationwide, and employment of machinists is projected to grow 8 percent from 2010 to 2020 to about 468,000 jobs, according to the Bureau of Labor Statistics.

The average annual salary for a machinist locally is $35,217. Machinists may expect a starting annual salary of $29,002, which should grow with time to $41,431, according to the Bureau of Labor Statistics. And if they are willing to commute to other areas of the state, the average annual salary is $51,993, according to the Bureau of Labor Statistics.

Even as BCCC works to expand its campus-based machinist program, the college is working through its Business and Industry Services to meet the demands of local industries currently employing machinists.

Lincoln is training 45 machinists at Stanadyne to give those workers the chance to brush up on their skills and learn new skills that they need to work with more-advanced machining equipment recently acquired by Stanadyne.

In July, Lincoln will begin training some two dozen new employees at Weir Valves and Controls to update those workers’ skills.

For more information about BCCC’s machinist classes, contact Lincoln at 252-940-6279 or by email at matthewl@beaufortccc.edu. For information about enrolling in and registering for classes at BCCC, contact Daniel Wilson, director of admissions and recruitment, at 252-940-6233 or by email at danielw@beaufortccc.edu.